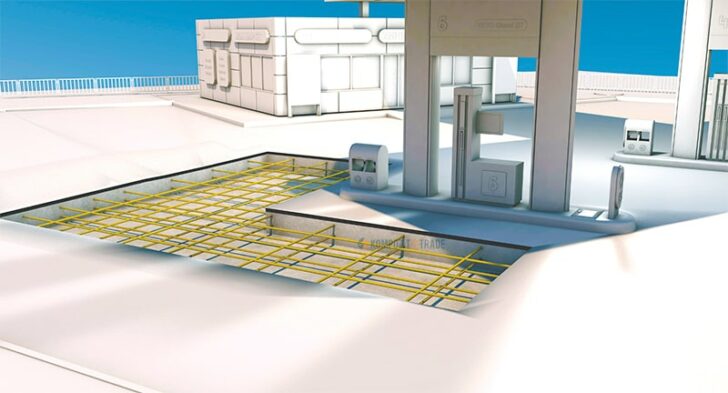

Company Kompozit 21 trade is an experienced fiberglass rebar and mesh manufacturer. Our product range includes 11 sizes of rebar, 12 sizes of reinforcing mesh and 4 sizes of masonry mesh.

Our company’s main priority is a strict production control to get a cool product, which we are not ashamed of! And our margin is not that big, so we can offer our customers a quality product at competitive prices.

Another advantage: the main production is located in Russia and the cost of goods is formed in rubles. Because of the low ruble exchange rate, our prices are even more attractive for builders from other countries.

Thus, choosing our fiberglass rebar materials instead of metal ones, you save several times:

- first, due to the fact that fiberglass rebar is up to 68% more efficient than metal;

- secondly, because of our flexible pricing policy!

On our website you can find a list of products, applications, examples of objects where our rebar and mesh were used.

Leave a request to get a price list and to calculate the cost of delivery.